OUR FOCUS ON DECARBONIZATION

As a global leader and innovator in our industry, we remain committed to developing low-carbon circular aluminum packaging solutions and satellite instruments for environmental monitoring. Our growth potential relies on our ability to transform ourselves into a fully circular and decarbonized business, an ambition that is reflected in our ambitious near-and long-term science-based targets. Our Climate Transition Plan outlines how we will collaborate internally and externally to achieve Net Zero carbon emissions prior to 2050.

BALL'S CLIMATE TRANSITION PLAN Report

Accelerating decarbonization through ambitious action within the aluminum industry

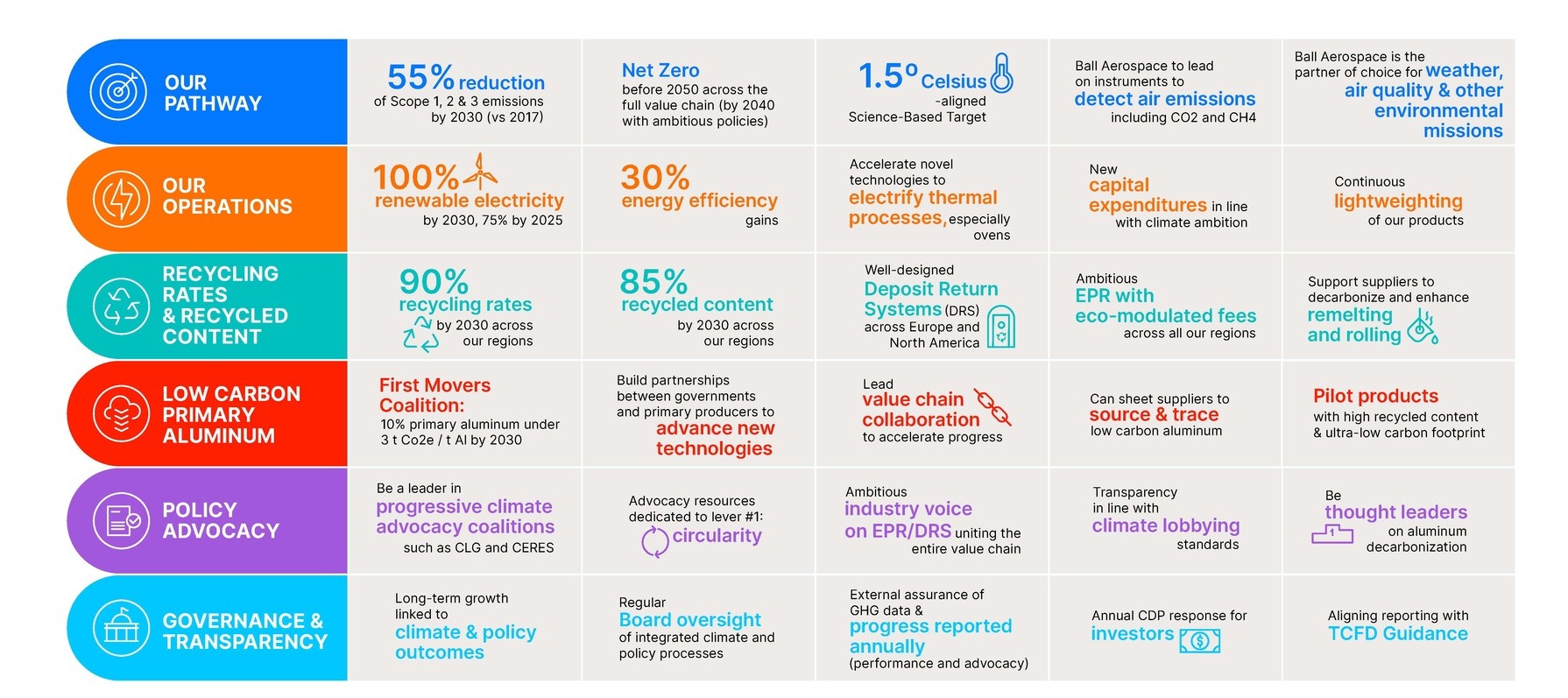

Climate Transition Plan At A Glance

Plan A

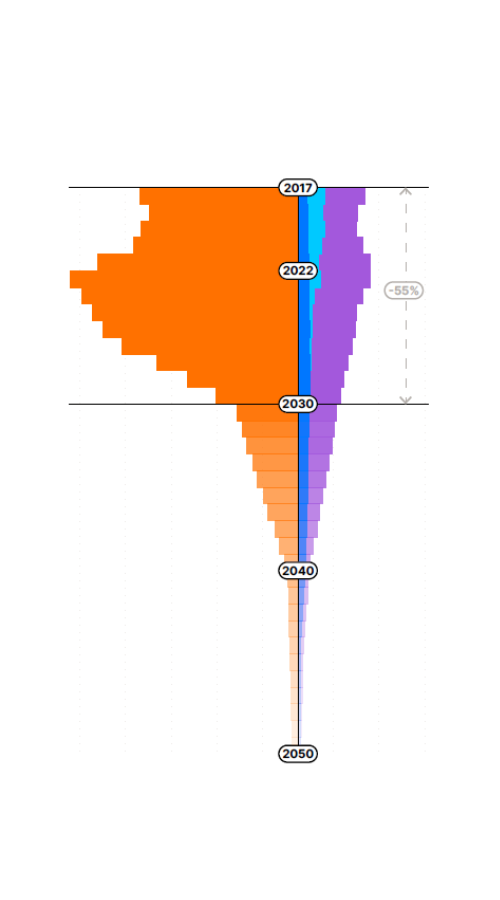

This chart demonstrates Ball’s core path to net zero carbon emissions (Plan A). Scope 3 emissions related to aluminum procurement account for nearly 75% of Ball’s total GHG footprint. To reduce this emissions source we need to rethink the entire value chain and identify how all aluminum can be kept in a closed-loop recycling system. With the use of renewable electricity, 30% energy efficiency gains and the start of a transition to alternative heat sources, 55% of Ball’s Scope 1 and 2 emissions will be addressed by 2030.

At a macro level, Plan A foresees continued and rising public support for climate change action and an accelerated transition to a circular, low-carbon economy. At the meso level Plan A foresees beverage brands increasing their commitments to reusable and/or high recycled content packaging and governments facilitating a rise in collection, recycling, and remelting capacities. We anticipate these trends will rapidly lead us to a low-carbon primary aluminum sector.

Ambition and credibility are the foundation of Ball’s sustainability strategy. Following the publication of our Climate Transition Plan, Ball will submit its Net Zero commitment for validation by the Science Based Targets initiative (SBTi). SBTi's Net-Zero Standard is recognized and supported by several leading sustainability-related organizations, including CDP, Ceres, the World Resources Institute, and the United Nations Global Compact.

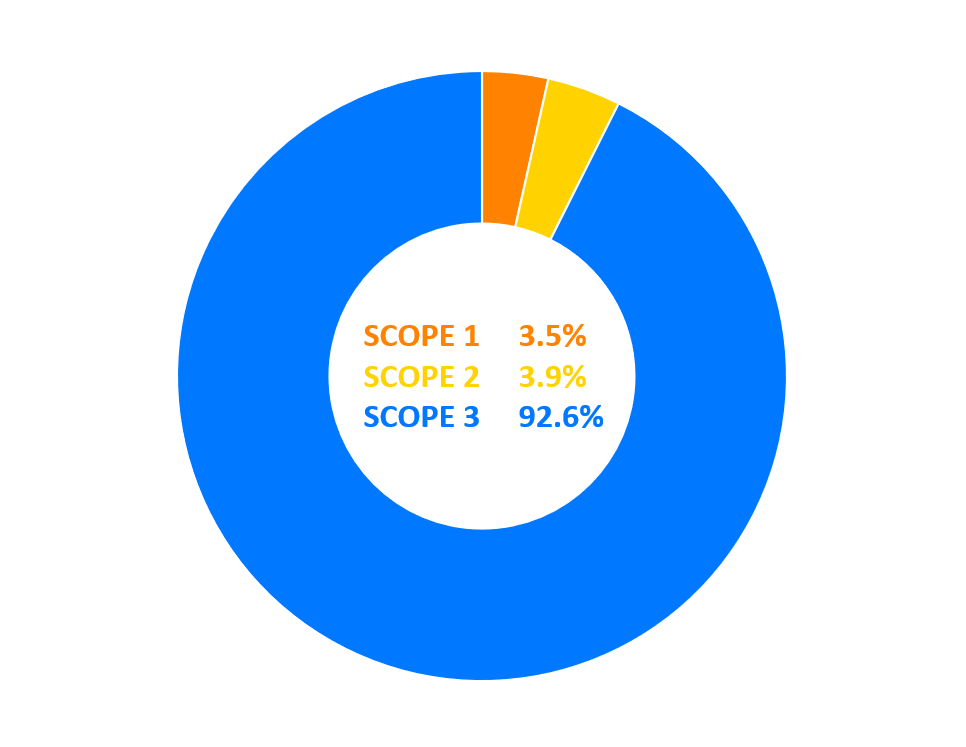

Our Carbon Footprint

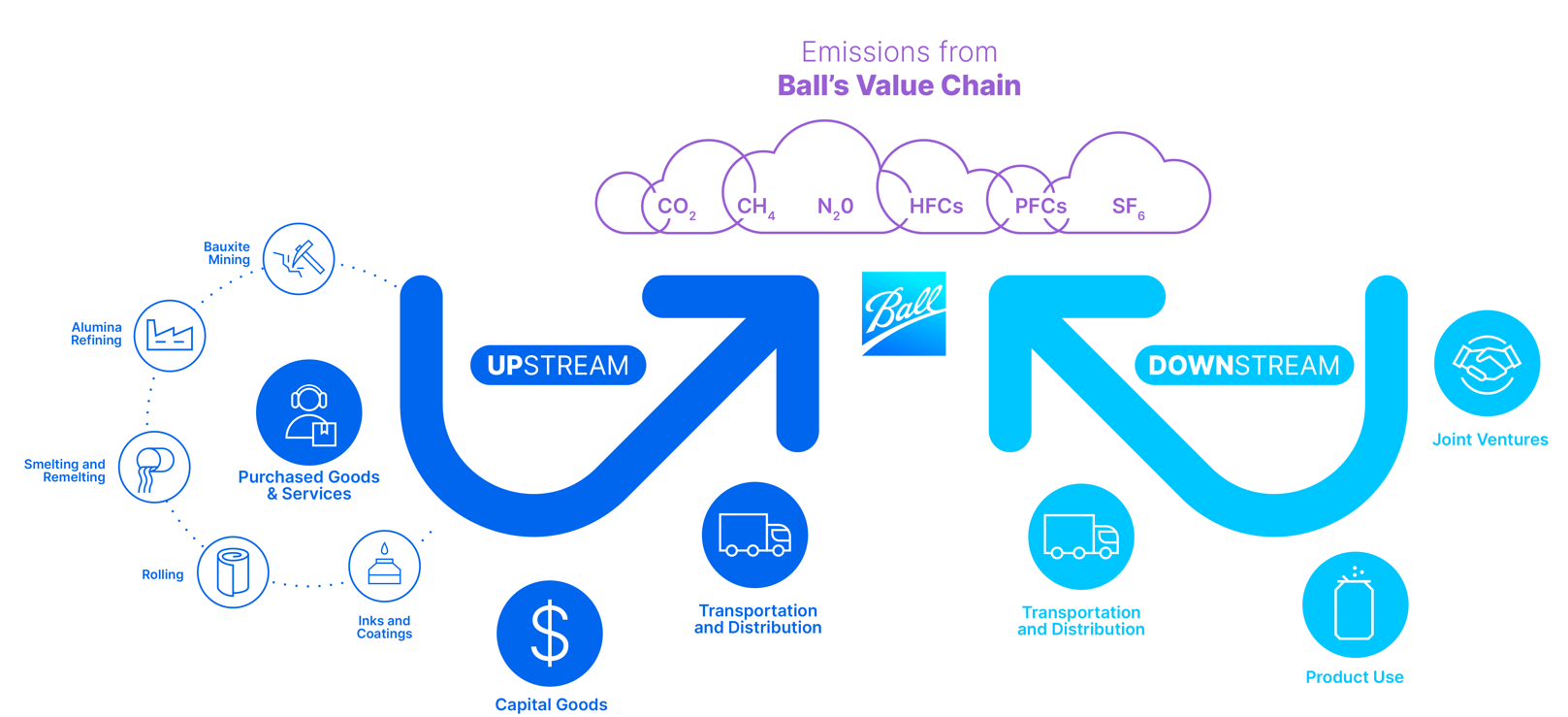

Ball’s carbon footprint is composed of the GHG emissions emitted from our direct operations (Scope 1 and 2) and from our value chain (Scope 3). Like many organizations, the majority of Ball’s emissions come from our value chain. As a result, the Climate Transition Plan focuses heavily on the decarbonization levers that exist within our value chain, particularly the opportunities to decarbonize the aluminum manufacturing processes.

1.5 Degree C Compliant Science Based Targets

In 2019 we set a target of achieving a 55% absolute reduction in GHG emissions from our own operations by 2030, despite expectations that the business will experience unprecedented growth during this period.

The target aligns with the latest climate science reported by the Intergovernmental Panel on Climate Change, a global body of climate experts which has announced that global warming should be limited to 1.5°C above pre-industrial levels if its worst impacts are to be avoided.

Our 1.5°C target was approved in early 2020 by the Science Based Target Initiative, an international governing body that independently assesses and approves companies’ GHG goals. We are the first aluminum can manufacturer to adopt a science-based target. We will aim to meet the 55% target in two main ways: by switching to renewable energy and by improving energy efficiency in our manufacturing processes.

VALUE CHAIN TARGET UPDATES

When we first submitted our science-based targets for approval our value chain target was aligned to a 2°C scenario, resulting in a commitment to cut GHG emissions 16% across our value chain by 2030. We came to understand that our value chain goal had become out of date, both in terms of what the latest climate science suggests and in what our customers expect from Ball. Between 2020 and 2023, almost all our key aluminum beverage and aerosol customers published aggressive net zero plans, often setting out to achieve net zero emissions by 2040. To further demonstrate how aluminum packaging can help achieve our customers’ carbon reduction objectives, we decided to update and expand our 2030 climate goals. We increased the level of ambition of our value chain science-based target from a 16% to a 55% reduction in absolute GHG emissions by 2030.

Around 93% of the GHG emissions associated with our products come from within our value chain rather than our own operations. We collaborate with our value chain partners to make a difference in this area, both ‘upstream’ in the products and services we purchase from suppliers, and ‘downstream’ in the way our products are collected, sorted and recycled. We are able, for instance, to work with various stakeholders to cut GHG emissions by lightweighting our products and reducing the amount of material needed, increasing recycling rates and recycled content (as we explain in our Real Circularity webpage), and utilizing low-carbon primary aluminum.

Emissions Reductions in Our Own Operations

In order to meet our science-based target in the face of unprecedented growth, Ball has set two critical goals that must be achieved in order to reduce our absolute emissions by 55% by 2030:

- Achieve 100% renewable electricity globally by 2030, with an interim target of 75% by 2025.

- Achieve 30% energy efficiency improvement (electricity and natural gas) in can manufacturing (2020-2030).

For more information regarding our efficiency projects, visit the Resource Efficiency webpage.

Click the banner below to learn more about how we are executing our renewable energy and efficiency initiatives.

Achieving 100% renewable electricity globally by 2030 is a pivotal step in achieving our Science-Based Target. We’ve also set an interim target of achieving 75% renewable electricity globally by 2025 to showcase our rapid decarbonization efforts in our largest markets. Renewable energy is not only critical to Ball’s carbon footprint but is also an important component to reducing the carbon footprint of our packaging. In our Life Cycle Analysis work, we have demonstrated that use of 100% renewable electricity can reduce the carbon footprint of an aluminum beverage can between 10 and 18%, depending on the region of manufacturing and type and size of the package.

Operating through the lens of Drive for 10 and our EVA® discipline, Ball is committed to utilizing renewable electricity. In 2022, Ball successfully secured 28% renewable electricity coverage across all our regions. Where possible and financially viable, Ball continues to pursue Virtual Power Purchase Agreements (VPPA) with renewable energy developers to bring new wind and solar to the grid. In 2022, Ball received over 285,000 MWh of renewable electricity from a VPPA wind power project in North America, and over 250,000 MWh of renewable electricity in Spain and Sweden. Through a recent VPPA announced in May 2022, we expect to receive approximately 600,000 MWh of clean energy each year from a new Texas-based wind energy project.

To meet the electricity demand of our growing businesses as well as efforts to electrify thermal energy needs and eliminate the use of natural gas, we continue to negotiate additional VPPAs and also diversify our renewable energy strategy. Our energy procurement team evaluates direct supply opportunities with our utility partners and evaluates the potential for on-site renewable energy production in new as well as existing facilities. Our strategy centers on fostering the development of new, additional renewable energy capacity while using the purchase of unbundled RECS/GOs to meet regional goals and the needs of our customers in the immediate term.

In order to drive resource efficiency and cost reduction, as well as limit our needs for additional renewable electricity, energy efficiency also remains a key component of our strategy.

We are committed to reducing the amount of energy required to produce each beverage can in our manufacturing plants by 30% during this decade. This primarily means cutting back on our use of electricity and natural gas.

To learn more about our energy efficiency approach, please visit our Resource Efficiency page.

EMISSIONS REDUCTIONS IN OUR VALUE CHAIN

Detailed insights in our Scope 3 emissions allow us to identify relevant risks and opportunities associated with emissions from our value chain, develop reduction plans and engage value chain partners in meaningful mitigation actions.

In 2021, we articulated our vision to achieve a global recycling rate of 90% for beverage cans, bottles and cups, and an average 85% recycled content in those products. These two levers, combined with additional GHG emission reduction successes by the primary aluminum industry, will contribute to our updated 55% reduction target in our absolute Scope 3 GHG emissions.

Changes to recycling infrastructure and legislation take time, and we do not expect recycling rates and recycled content for our products to increase in a linear way during this decade. Instead, legislation in areas such as deposit return schemes will be implemented in various markets from 2024 on and additional remelting capacity may come online soon thereafter.

In 2021, we participated in the Aluminium for Climate initiative, part of the Mission Possible Partnership, which is co-led by the World Economic Forum. This initiative is developing Net Zero pathways for the sector in direct collaboration with the industry. In addition to transitioning to fossil free energy sources, an additional way of helping decarbonize direct emissions resulting from primary aluminum production is through the use of inert anode technology for aluminum smelting. Currently, this technology is not commercially available. In 2021, we set up a collaboration with a primary aluminum producer to use several tons of aluminum made with inert anode technology from an industrial pilot to produce aerosol cans with a reduced carbon footprint.

In 2022 Ball served as a founding member of the World Economic Forum’s First Movers Coalition and pledged to buy 10% of all primary aluminum as low-carbon aluminum (less than 3 t CO2e/t cradle to gate) by 2030. This commitment helps to ensure investment in new technologies to accelerate decarbonization within the aluminum value chain.